Compare Variation in Process Performance by Using Which Chart

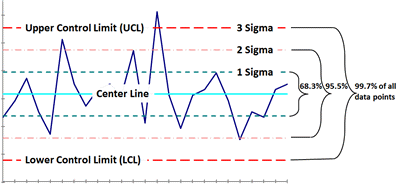

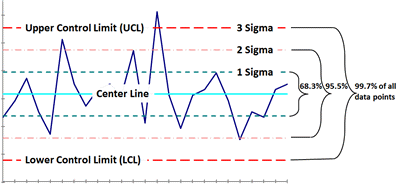

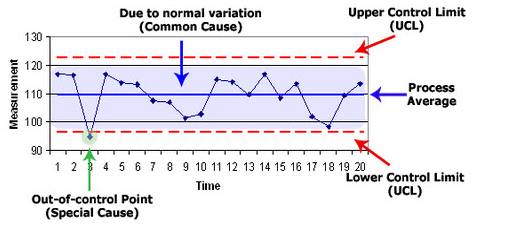

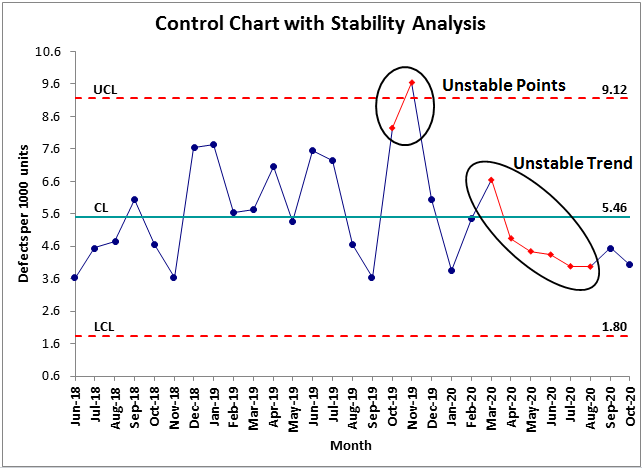

The Control_Chart in 7 QC Tools is a type of run_chart used for studying the process_variation over time. Statistical process control SPC Define and describe the objectives of SPC including monitoring and controlling process performance tracking trends runs etc and reducing variation in a process.

Problem Solving Worksheet Lean Six Sigma Lean Sigma

Using the data you gathered evaluate your performance and talk with your team on how you could improve on the next project.

. 15Five is a standalone performance management tool designed to help your people quickly master this critical business process. Download Full PDF Package. In Six Sigma we want to describe processes quality in terms of sigma because this gives us an easy way to talk about how capable different processes are using a common mathematical framework.

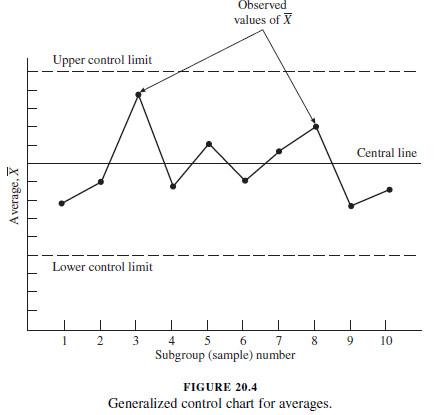

When a process is in statistical control the within subgroup variation is a good estimate of the overall process variation ie σ s. Lets move on to Process 2. If the chart indicates that the monitored process is not in control analysis of the chart can help determine the sources of variation as this will result in degraded process performance.

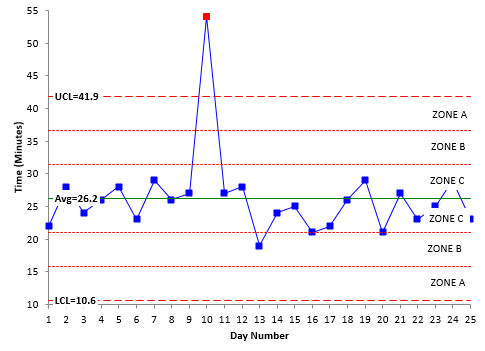

It also automatically warns when performance deteriorates and can assist with long-term defect reduction identification of special or assignable causes reduction or elimination of causes of variation and achievement of a level of performance as close to target as possible. Cp and Cpk are considered short-term potential capability measures for a process. Analyze attributes data using logit probit logistic regression etc to investigate sources of variation.

They are giving you the same information. Cpk is essentially the same as Ppk in this case. In other words it allows us to compare apple processes to orange processes.

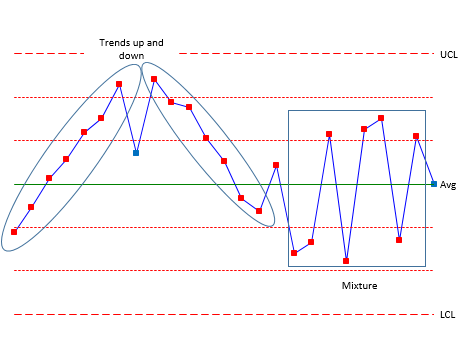

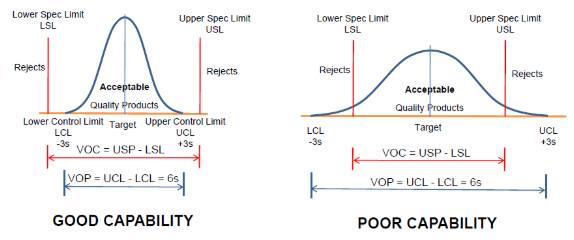

Random variation or out of control and needing attention. A capability analysis is only valid when performed on a stable process. In our business any process is going to vary from raw material receipt to customer support.

The range chart for Process 2 is shown in Figure 7. Advanced Statistics Expectancy -Expectancy tells you what you can expect to make win or lose on every trade. The engineer examines the R-Chart first because the control limits on the X-Bar charts are inaccurate if the R-Chart indicates that the process variation is not in control.

Additional tests make the chart more sensitive to detecting special-cause variation but also increases the chance of false alarms. Full PDF Package Download Full PDF Package. Just because the building is over doesnt mean youre done with the planning process.

Assess the effectiveness of a process change. With this smart WooCommerce product-compare module you can customize the compare buttons using the settings of the widget from Elementor. This is classified as per recorded data is variable or attribute.

They will have absolute liberty to select attributes for comparison. Using information from these statistics you can better understand which processes need improvement where you have opportunities for improved productivity and how to prioritize improvement activities. 31 Full PDFs related to this paper.

A process that is stable but operating outside desired specification limits eg scrap rates may be in statistical control but above desired limits. Capability Cp and performance Cpk indices go beyond elemental quality control to illustrate a processs ability to meet specifications. With control charts it is easy to compare shifts in the process mean and changes in the process variation.

Communicate the performance of your process during a specific period of time. Badges Module Pro Let your customers know about the sale of products by using ShopEngines badges module. Z-Score - Z-Score is used for calculating the ability of a trading system to generate wins and.

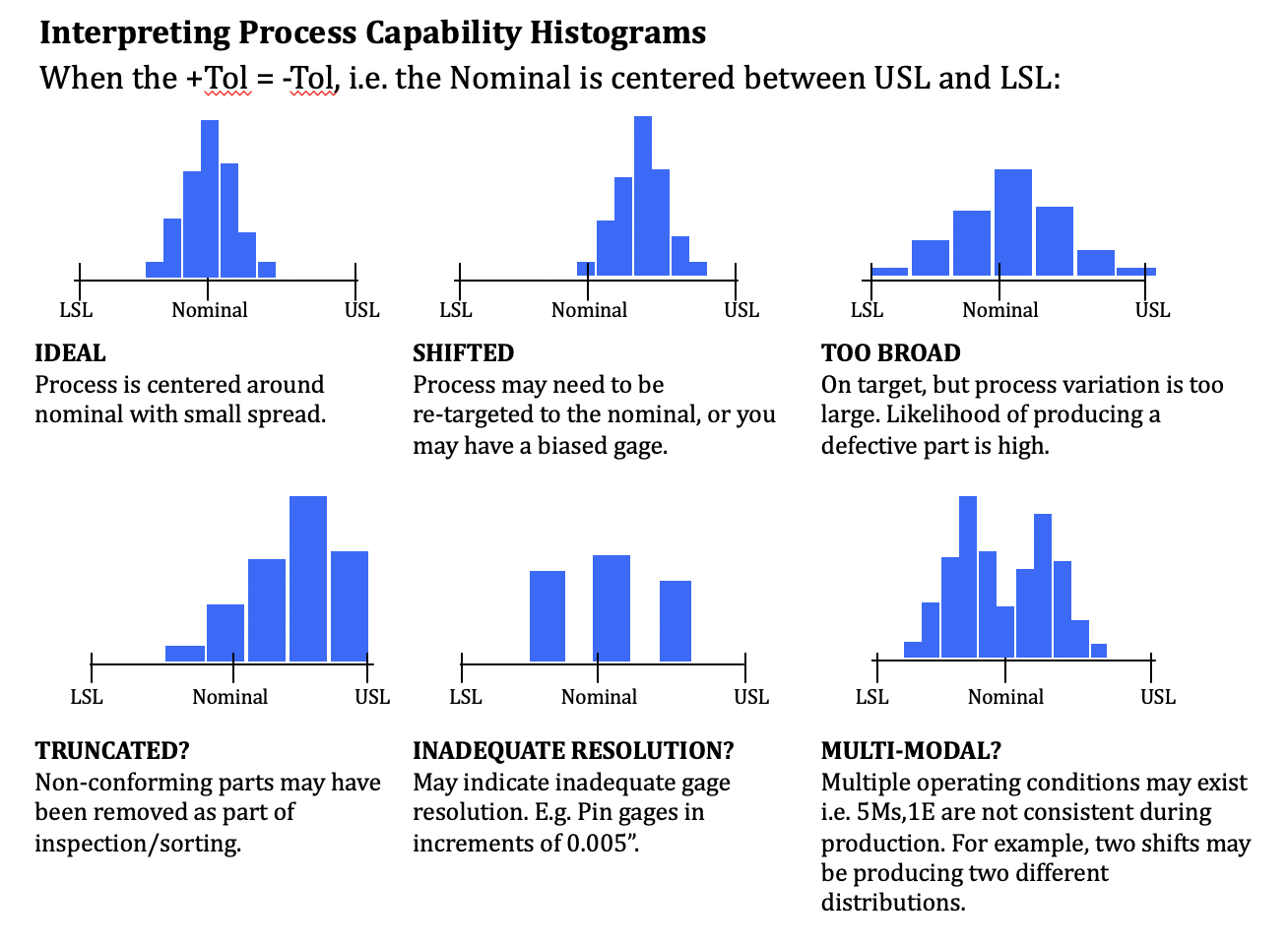

The type of chart used will be dependent upon the type of data collected as well as the subgroup size as shown by the table below. The process capability is a measurable property of a process to the specification expressed as a process capability index eg C pk or C pm or as a process performance index eg P pk or P pmThe output of this measurement is often illustrated by a histogram and calculations that predict how many parts will be produced out of specification OOS. Most tests beyond test 1 are only appropriate when trying to bring a process under control.

IASSC Six Sigma Black Belt. The software helps managers and employees equally well guiding both through the review process at a variety of intervals. If process variation eg.

Standard Deviation -Standard Deviation is a statistical measure of volatilityIt shows how much variation or dispersion there is from the mean expectancy. For example applying tests 1 2 5 6 raises the false alarm rate to once every 9175 observations. 15Five boasts a colorful fun and easy-to-use interface and is unique among the top five for basing its entire.

A short summary of this paper. The R-Charts for the three machines indicate that the process variation is in control no points are out of control and all points fall within the control limit in a random pattern. From two different shifts is captured within one subgroup the resulting control limits will be wider and the chart will be insensitive to process shifts.

AIAG Statistical Process Control SPC 2nd Edition. Process 2 Range Chart.

Stability Analysis Versus Capability Analysis

Voice Of The Customer Voc Dfss Roadmap Lean Six Sigma Business Performance Change Management

Cp Cpk Pp And Ppk Know How And When To Use Them

Control Charts Everything You Need To Know

Lean Six Sigma Black Belt Lean Six Sigma Change Management Business Management Degree

Step 4 Interpret The Graph Pattern And Cpk Value Process Capability Statistical Process Control Excel Templates

Control Chart Rules And Interpretation Bpi Consulting

Posts About Tqm On Catatan Kuliah Process Chart Change Management Statistics Math

Six Sigma Breakthrough How To Plan Change Management Lean Six Sigma

Guide To Statistical Control Charts Juran

Control Chart Rules And Interpretation Bpi Consulting

Variation In Each Process Before Capacity Per Hour Compare To Bench Mark Target Per Hour Industrial Engineering Engineering Tools Charts And Graphs

How To Create And Read An I Mr Control Chart

Pareto Chart With Example 3 Real Life Pareto Chart Examples With Explanation Chart Six Sigma Tools Software Testing

How To Measure Process Capability And Process Performance

A Guide To Process Capability Cp Cpk And Process Performance Pp Ppk 1factory

Digital Six Sigma Dmaic Improvement Process Objective Main Activities Key Deliverables Team Charter Project Problem Solving Worksheet Lean Six Sigma Lean Sigma

Analysis Of Future State Map Value Stream Mapping Process Improvement Process Control

Control Chart Rules Process Stability Analysis Process Control

Comments

Post a Comment